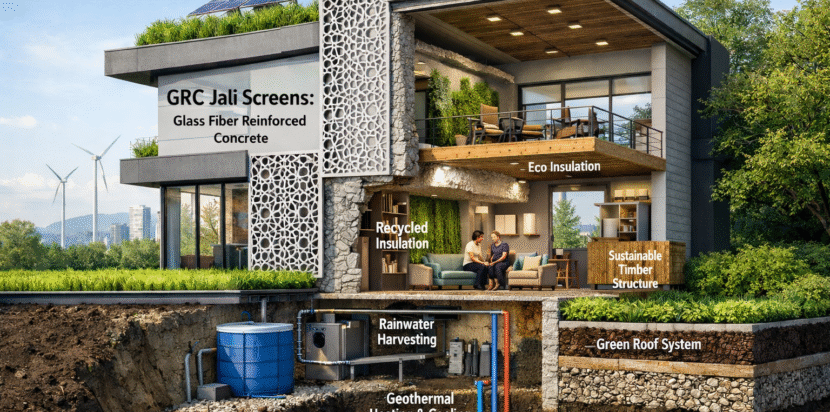

The Role of GRC in Sustainable Construction: Top Eco-Friendly Material Benefits

Sustainable construction is no longer just a trend—it has become a necessity in modern architecture. As the construction industry moves toward environmentally responsible practices, Glassfiber Reinforced Concrete (GRC) has emerged as a powerful material supporting green building goals. Known for its durability, versatility, and reduced environmental impact, GRC plays a significant role in eco-friendly construction projects worldwide.

What Is GRC?

Glassfiber Reinforced Concrete (GRC) is a composite material made from cement, fine aggregates, water, and alkali-resistant glass fibers. These fibers enhance strength while allowing the material to remain lightweight and flexible in design. Because of its performance and sustainability benefits, GRC is widely used in façades, cladding panels, screens, domes, and architectural elements.

Why GRC Is Important for Sustainable Construction

Sustainable construction focuses on minimizing environmental impact, reducing resource consumption, and increasing building efficiency. GRC supports these objectives in multiple ways, making it a preferred choice for green architecture.

Top Eco-Friendly Benefits of GRC

1. Reduced Material Consumption

GRC components are significantly thinner than traditional concrete, which means less cement and raw material are required. This reduction directly lowers resource extraction and material waste, contributing to sustainable construction practices.

2. Lower Carbon Footprint

Because GRC is lightweight, transportation and installation require less energy compared to conventional concrete or stone. Reduced fuel consumption during logistics helps lower overall carbon emissions in construction projects.

3. Long Service Life and Durability

GRC is highly resistant to weathering, corrosion, fire, and UV exposure. Its long lifespan reduces the need for frequent repairs or replacements, minimizing material waste and long-term environmental impact.

4. Minimal Construction Waste

GRC elements are typically manufactured in controlled environments with precise dimensions. This prefabrication process reduces on-site waste, dust, and excess material, making construction sites cleaner and more eco-friendly.

5. Energy Efficiency in Buildings

GRC panels can be designed with insulation layers and shading elements that help regulate indoor temperatures. Improved thermal performance reduces reliance on heating and cooling systems, leading to lower energy consumption.

6. Design Flexibility Without Environmental Cost

GRC allows architects to create complex shapes, textures, and finishes without using heavy natural stone or high-energy materials. This design freedom supports creativity while maintaining sustainable material choices.

7. Recyclable and Reusable Potential

Many GRC components can be recycled or repurposed at the end of their life cycle. This supports circular construction principles and reduces landfill waste.

GRC and Green Building Standards

GRC contributes positively toward green building certifications by supporting:

- Resource efficiency

- Reduced embodied energy

- Improved building performance

- Sustainable material usage

Its compatibility with modern eco-friendly construction techniques makes it suitable for residential, commercial, and institutional projects.

Comments are closed